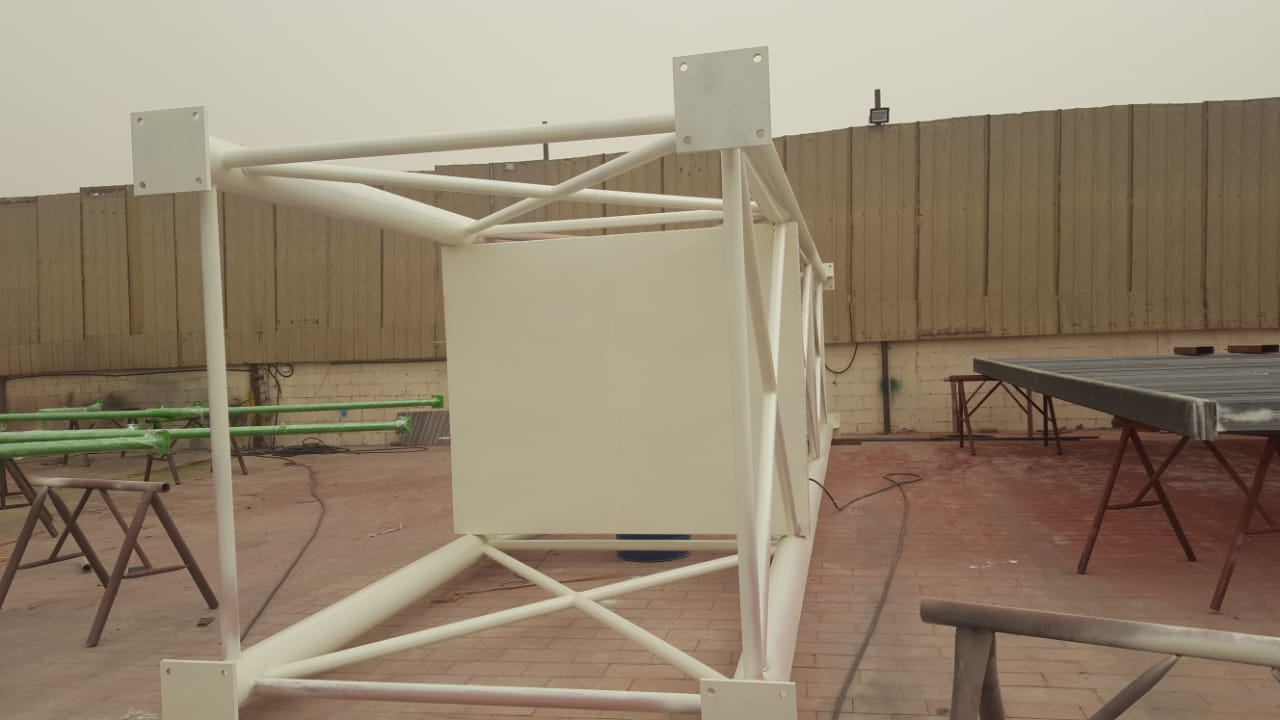

Leading Service Providers in Metallizing | Abrasive Blasting | Heavy fabrication | Industrial Painting

We are Professionals in Protective Coatings like Abrasive Blasting, Thermal spray coatings & Industrial Painting since a decade from UAE and India.